We have likely all been in a situation where something unexpected happens and the situation results in costing a couple hundred or thousand dollars. Yet, after that situation occurs, most of us fall back into a rhythm carrying on with the day-to-day. If you’re managing a fleet, you need to make costs as manageable as possible to stay on budget. Data from oil samples can provide a number of insights that will help you plan for repairs.

Many oil manufacturers provide in-house lab testing for a reasonable price. Gathering a sample is as easy as:

- Ordering a sample kit from the manufacturer

- Gathering the sample

- Receiving the results and making data-driven decisions

Your lubricant expert will be able to suggest programs based on what you are looking to achieve. A few examples could include, identifying contamination (soot test), detecting proper drain intervals (TBN test), and determining moisture content (% water).

Soot Test

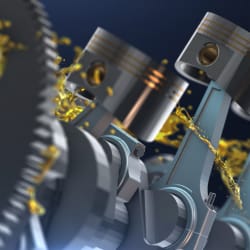

Soot may be formed during the combustion process. Poor efficiency of combustion will result in a high level of soot which translates to several negative consequences:

- Improper air to fuel ratios

- Worn or stuck rings

- High-temperature operation

- Over-extended drain intervals

If results come back with Soot measurement of over 2%, contact your lab manager for recommendations.

TBN (Total Base Number) Test

As oil is used, acids are created due to oil oxidation and in turn, the TBN level drops. TBN is important because it neutralizes the acid. The higher the TBN remaining in the lubricants, the more acid the oil is able to neutralize. If you overheat or over-extend drain intervals, you will notice a drop in the TBN value. Monitoring the TBN helps determine the proper drain interval for the vehicle.

A TBN value below 4 is an indication that the additive package in the oil has been used up and the oil should be changed.

% Water

The water inside engine oil can reduce or eliminate the lubricity of the oil. Dependent on the percentage of water present, metal surfaces in the engine will make contact and rub together resulting in wear and ultimately engine failure. Typically the oil will appear milky if this is the situation.

If results come back over 0.1% water, the oil should be changed and the source of the water entry should be investigated and repaired.

Conclusion

The soot, TBN, and % water are all great tests to understand the health of your lubricant, and to provide the peace of mind of knowing when to expect repairs. Implementing an oil analysis program will be able to show data trends and provide greater insights into your fleet.

About the Author:

Scott Vanevenhoven

OilChek® Lab Manager

Scott Vanevenhoven is the OilChek® Lab Manager of U.S. Lubricants. Scott has over 20 years of lab experience predominantly in the oil and energy industry. Scott graduated with a Bachelor of Science degree in environmental science and a minor in chemistry.