Evaluating Drain Intervals

Finding the balance between following OEM oil change recommendations and adjusting maintenance schedules to reduce operational costs — while not compromising engine life — can be difficult to navigate. The process is even trickier when you add in material and labor shortages. So, what is the best way to optimize drain intervals? We recommend two solutions that have been used for over 65 years to help you feel confident about extending engine drain intervals.

1. Analyze Your Oil

A great first option is participating in our OilChek® Oil Analysis Program. With several variables impacting the life of your fleet, such as type of driving, weather conditions, and engine type, establishing when your fleet requires an oil change can result in large savings. There are various tests that can be conducted to identify proper drain intervals. Our customers who have participated in our oil analysis program have seen incredible results. For example, one of our customers almost doubled their mileage between drain intervals, saving time and money for their business.

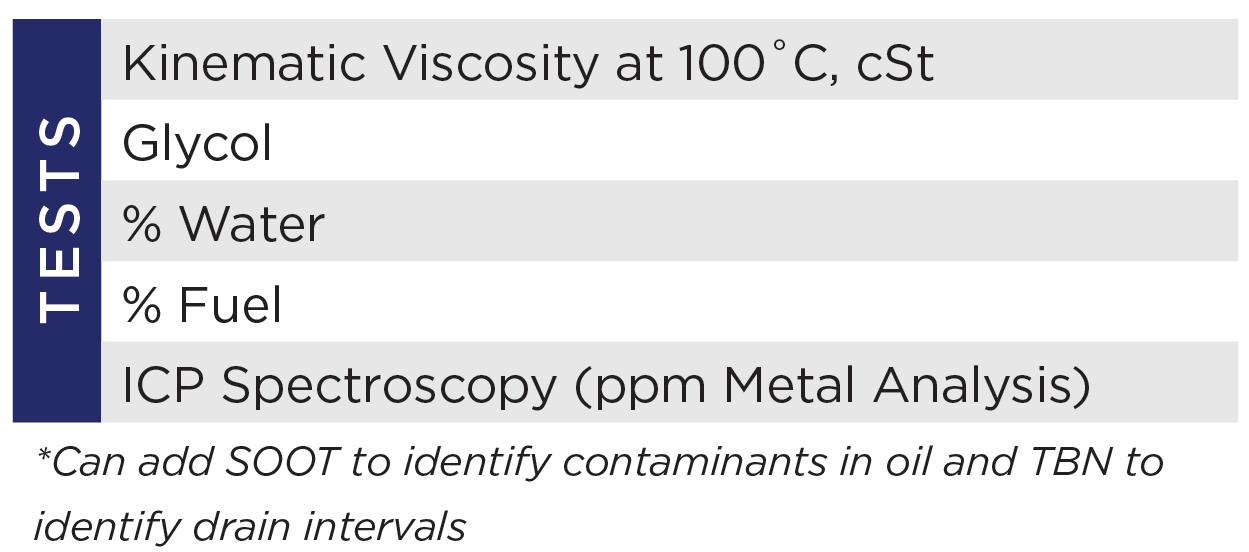

Engine Oil Analysis Testing

Our ISO 9001:2015 certified lab uses quality testing equipment to generate accurate results. You will receive comprehensive analysis reports outlining the state of your oil, any contaminants present, and recommended next steps. To identify proper drain intervals, our lab will conduct a series of oil analysis tests:

2. Identify Products to Optimize Drain Intervals

Another solution is working with one of our business development specialists to tailor a product mix specific to your fleet. They’ll work with your team to identify solutions that will support extended drain intervals, lower total cost of ownership, and increase the longevity of your fleet. Each major brand and oil type provides a different niche. Together we’ll find the solution that is best for your fleet.

Other Factors to Consider

If you plan to evaluate extending the life of your drain interval, consider the following:

- Consult the manufacturer before extending the interval if your equipment is under warranty.

- Evaluate both the risk and the reward of extending the drain interval.

- Assess whether maintenance services can withstand the time frame of the drain interval and if you’ll need to adjust service intervals for other components.

Use this list to determine if and how you can extend drain intervals and reduce operational costs while keeping your fleet on the road.