Live zone sampling is a new trend in oil analysis to obtain the most representative sample. This process entails collecting the sample from where the fluid is moving. For proper analysis, samples should be taken at the same place and with the same depth each time. In this article, we will be going into detail on how to obtain a proper live zone sample and the benefits of using a multipoint sampling approach.

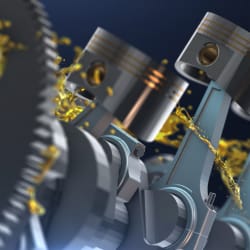

Hydraulic circuits are more than just a reservoir attached to a series of pumps, hoses, and power transmission equipment; they are an ever-changing environment in which the lubricant must achieve its goal of protecting all system components. For this reason, live zone sampling, as well as a multipoint sampling approach are important in understanding the overall health of the lubricant and critical components.

Live zone sampling: The practice of collecting oil samples from areas in the oil circuit that have active flow.

How to obtain the live zone sample:

The collection point may be in the reservoir, six inches below the oil surface, or the sampling point may be from a hard-tapped port found on the pump intake pipe. Modern live zone sampling practices must pull from areas of flow to determine what the quality of the lubricant is when the fluid is approaching critical components.

Collecting samples from active flow provides a realistic picture of:

- Moisture content

- Particulate contamination

- Oil temperature

- Overall condition of lubricant

Watch this video to learn how to take a live zone sample!

Multipoint Sampling Approach

A multipoint sampling approach helps to provide information on component health by allowing the maintenance team the ability to monitor wear metal analysis on each critical component, identifying issues in machine health.

A best practice is to place sample points before and after critical system components. This allows maintenance personnel the ability to analyze condition monitoring results and relate them to pump, valve, motor, or cylinder health. This is commonly done by hard tapping into pipes located before and after critical components.

Hydraulic circuit modification should include a permanently mounted sample port. This is not a simple task, but it does allow for samples to be taken at the same place and with the same depth in the lubricant every time it is sampled. Adapting oil sampling practices to a live zone method and multipoint sampling approach will enable predictive maintenance and help remove the root causes of failure.

Single-point sampling from the drain plug of a hydraulic reservoir is no longer regarded as a proactive approach to oil sampling. The information provided from this type of sampling may reflect conditions that are no longer present in the system, whether good or bad.

Conclusion

Live zone sampling paired with the multipoint sampling approach is the best way to analyze the health of your fluid and components. This type of sampling provides information on the condition of the lubricant, oil temperature, potential particle contamination, and moisture content. The multipoint sampling approach additionally monitors the health of key components to identify root causes of failure.

About the Author:

Andrew Martin

Andrew Martin

Industrial Product Engineer

Andrew Martin is the Industrial Product Engineer at U.S. Lubricants. Prior to U.S. Lubricants, Andrew was a Project Lead at Pinnacle and received his degree in Mechanical Engineering from the University of Illinois at Urbana-Champaign. Andrew is MLT I/MLA I certified. To learn more or connect you can find Andrew Martin on LinkedIn.