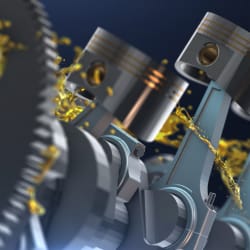

Managing the contamination of lubrication is widely known as one of the most important factors in maximizing equipment health. While selecting the appropriate lubrication provider can play an important role in the quality of the lubrication in your facility, what happens at your facility, is just as critical. Four key stages of the fluid life contribute to the contamination of the lubricant life cycle:

- Delivery and storage of lubrication

- Dispensing and transfer of lubrication

- Management of lubrication in use

- Disposal of used lubricants

Delivery and Storage of Lubrication

Controls at each step of your delivery and storage process are critical to maximizing efficiency while reducing contamination. We recommend working with your lubricant provider to ensure the fluid being delivered is appropriate for specific needs and applications of the machine or equipment. This may include additional processing, including validation testing, of the fluid prior to receipt at the facility. When the fluid is received in a suitable condition, it must then be stored properly. Dedicated indoor storage that is clean, organized, and dry is recommended. Appropriate labeling, color coding, and consistency are the next steps in continuously managing the lubricants.

Dispensing and Transfer of Lubrication

The risk of contamination is greatly increased with any dispensing or transferring of lubricants. Several minor, non-costly changes can lead to a big improvement in reducing contamination such as:

- Keeping lines, pumps, and their surrounding environment clean

- Covering any fittings, couplers, or containers

- More expensive options, which maximize cleanliness, include in-line filters or utilizing equipment specifically designed to reduce or remove contamination

Management of Lubrication in Use

Many devices are available on the market to help with your lubrication management. Filtration is the most common method to remove contaminants or prevent them from entering the process in an industrial setting. When researching filtration device options, selecting the appropriate filtration size, rating, and tolerance is critical to the success of cleanliness management. Breather filters are a great way to prevent contamination from entering the headspace of the machine sump. Management of fluid in use is three-fold:

- Remove contaminants generated by the process

- Eliminate contaminants entering the process

- Analyze the fluid

The end goal is to understand the cleanliness and quality of a lubricant to maximize fluid and machine health. Note that lubrication analysis is the best way to diagnose the quality of your machine’s internals.

Disposal of Used Lubricants

Appropriate labeling, color coding, and consistency are important controls to ensuring maximum machine health. They minimize the possibility of a handler grabbing the incorrect fluid or running short on quality lubricant. It’s equally important to maximize floor space and minimize the overall risk to your business. Minimizing risk includes disposing of used fluids in compliance with all local, state, and federal regulations.

Conclusion

It’s important to keep in mind that controls at each stage of the lubricant life cycle contribute to the longevity of your lubricant and leveraging lubrication analysis programs provide insight into the quality of your lubricant to determine contamination. Appropriate labeling, color coding, and consistency are important to maximize machine health. By implementing preventative steps, you can substantially impact the life of your lubricant.

About OilChek®

For over 40 years, the U.S. Lubricants’ OilChek® Oil Analysis Program has provided high-quality, state-of-the-art analyses of lubricating oil, fuel, coolant, and industrial products. The highly automated program provides a thorough examination of your lubricating system complete with written recommendations. We offer support and provide resources for the development, design, and research of manufactured equipment, assuring machine health®.

About the Author:

Joe Leistikow

Joe Leistikow

Technical Manager

Joe Leistikow is the Technical Manager for U.S. Lubricants. Previous to U.S. Lubricants, Joe was a Contracted Program Manager at Mercury Marine as well as holding positions within Sigma-Aldrich. A chemistry graduate from Ripon College, Joe also holds MLT/MLA 1 certifications. You can find Joe on LinkedIn.