Grease 101: Everything You Need to Know

You have likely seen it before—a thick, semi-solid substance applied to gears, bearings, and chains. But what exactly is grease, and why is it so critical for keeping our world moving? From the car you drive to the equipment that builds our cities, grease is an unsung hero of mechanical performance and longevity. This guide will walk you through the fundamentals of lubricating grease, explaining what it is, why it’s important, and how to understand its key properties.

We will explore the composition of grease, its wide-ranging applications, and the benefits it provides. By the end, you will understand how this essential lubricant protects machinery and helps you select the right type for any job.

What is Grease?

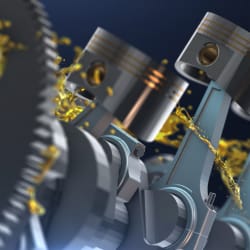

At its core, grease is a lubricant with a semi-solid to solid consistency. Grease is composed of three key components: first, a base oil that provides the primary lubricating action; next, a thickener that stabilizes and retains the base oil within the application; and finally, additives that enhance performance properties such as protection against wear, corrosion, and extreme pressure.

The thickener gives grease its characteristic texture and prevents the base oil from leaking or dripping away from the parts that need lubrication. This stay-in-place quality is what distinguishes grease from liquid lubricants like oil.

The Key Components of Grease

- Base Oil: This is the primary lubricating fluid, typically making up 80-95% of the grease. It can be mineral, synthetic, or bio-based, and it’s responsible for reducing friction between moving parts.

- Thickener: This component, making up 5-20% of the grease, is a solid or semi-solid material that forms a fibrous network to hold the base oil. Common thickeners include lithium, calcium, and polyurea. A popular and versatile choice is a lithium complex thickener, known for its high-temperature stability and water resistance.

- Additives: These are chemical compounds, usually less than 10% of the formula, that enhance specific properties. They can provide extra protection against wear, rust, oxidation, and extreme pressure.

Why is Grease So Important?

Grease plays a vital role in the health and efficiency of machinery across countless industries. Its primary function is to reduce friction and wear between moving components; however, its benefits extend much further. Products like our THRIVE line of greases are engineered to address these needs across a range of demanding environments.

Key Benefits of Using Grease

- Reduces Wear and Friction: By creating a protective film between metal surfaces, grease minimizes direct contact, significantly extending the life of parts like bearings, gears, and joints. THRIVE greases are formulated with enhanced EP (Extreme Pressure) properties for superior protection under heavy loads.

- Prevents Corrosion: Grease forms a barrier that seals out moisture and other corrosive elements, protecting metal parts from rust. THRIVE greases consistently achieve high ratings in standardized rust prevention tests.

- Resists Water Washout: High-quality greases like THRIVE are designed to stay in place even when exposed to water. This is crucial for equipment operating outdoors or in wet environments, ensuring continuous lubrication. Some THRIVE greases demonstrate excellent resistance, losing as little as 1.5% of their volume during intense water washout tests.

- Acts as a Sealant: The thick consistency of grease helps seal out contaminants like dirt, dust, and debris. This keeps the internal components of machinery clean and functioning correctly.

- Handles Heavy Loads: Certain greases, such as those in the THRIVE portfolio, are formulated with Extreme Pressure (EP) additives. These additives create a durable film that can withstand heavy, shocking loads without breaking down, preventing catastrophic equipment failure in demanding applications.

Common Applications Across Industries

Different industries require specific formulations to meet their unique needs. For example, grease is not a one-size-fits-all product. Different formulations are designed to meet the specific demands of various applications.

- Automotive: In the automotive world, grease is essential for lubricating chassis components, wheel bearings, U-joints, and ball joints. It must withstand a wide range of temperatures, from cold starts to the high heat generated during braking, while also resisting water and road salt.

- Construction and Agriculture: Heavy equipment used in construction and agriculture operates under some of the toughest conditions imaginable. These machines face heavy loads, shock impacts, dust, and moisture daily. Greases designed for these sectors often contain solid lubricants, like molybdenum disulfide (“moly”), which provide an extra layer of protection against wear when the machine is under extreme stress.

- Industrial Manufacturing: Industrial settings rely on grease for everything from conveyor belts and fans to pumps and presses. Here, consistency and reliability are key. Greases for industrial use must offer superior film strength to protect equipment running continuously, often at high speeds and temperatures. Compatibility is also a major consideration; using a grease that is compatible with others can simplify maintenance and prevent issues caused by mixing different thickener types.

How to Understand Grease Properties

When you look at a product data sheet for grease, you will see a list of technical specifications. While they may seem complex, they provide valuable information about the grease’s performance. For example, our THRIVE line of greases is formulated to deliver outstanding technical results, featuring high dropping points for superior high-temperature stability and excellent EP properties for enhanced protection under heavy loads.

- NLGI Grade: This measures the grease’s consistency or stiffness. Grades range from 000 (fluid) to 6 (very hard). An NLGI #2 grade is the most common, similar in consistency to peanut butter, and is considered a multi-purpose standard.

- Dropping Point: This is the temperature at which the grease becomes fluid enough to drip. A higher dropping point (e.g., 500°F) indicates better performance in high-temperature applications.

- EP Properties: Tests like the 4-Ball Weld Point and Load Wear Index measure a grease’s ability to protect against wear under extreme pressure. Higher numbers signify better protection for heavy-duty applications.

- Water Washout & Spray-Off: These tests measure how well the grease resists being washed away by water. Lower percentages are better, indicating the grease will stay in place to protect components.

Frequently Asked Questions (FAQ)

Q: What is grease made of?

A: Grease is composed of three main ingredients: a base oil (for lubrication), a thickener (to hold the oil in place), and additives (to enhance performance). The thickener acts like a sponge, releasing oil to lubricate parts as they move.

Q: What is the difference between oil and grease?

A: The main difference is the thickener. Oil is a liquid lubricant that flows freely. Grease has a thickener that gives it a semi-solid consistency, allowing it to stay in place and provide long-term lubrication without leaking. Oil is often used in enclosed systems like engines and gearboxes, while grease is ideal for open gears, chassis points, and bearings.

Q: How do I choose the right grease for my application?

A: To choose the right grease, consider the operating conditions:

- Temperature: Will the equipment run hot or cold? Check the grease’s dropping point and low-temperature pumpability.

- Load: Is the equipment subject to heavy or shock loads? If so, you will need a grease with Extreme Pressure (EP) additives.

- Environment: Will the equipment be exposed to water, dirt, or chemicals? Look for a grease with good water washout resistance and sealing properties.

- Speed: High-speed applications may require a different grease than low-speed ones. Always consult your equipment manufacturer’s recommendations.

Q: Can I mix different types of grease?

A: It is generally not recommended to mix greases with different thickener types (e.g., mixing a lithium complex grease with a calcium-based one). Incompatibility can cause the thickener to break down, leading to oil leakage and lubrication failure. If you must switch grease types, clean the old grease out of the application completely.