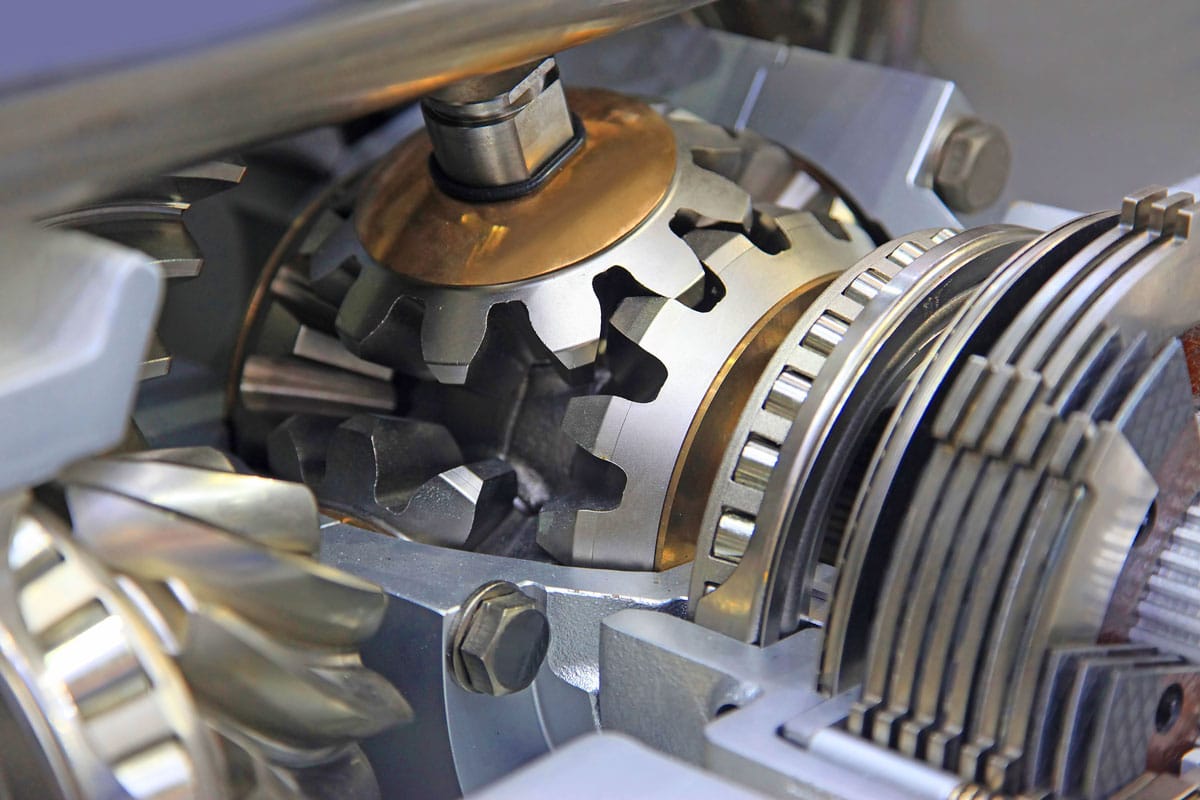

At U.S. Lubricants, we believe in helping our customers by only supplying the best products on the market. This means whether you choose a house brand or a major, it meets the industry specifications and has been tested for exceptional performance. We supply gear oil designed to protect vital components and be compatible with OEM-specified products. When it comes to lubrication, you shouldn’t suffice to average performance.

Conventional Gear Oil

Synthetic Gear Oil

Synthetic Long Drain Gear Oil

- Reduces development of foaming, rust, and corrosion

- Provides thermal stability to extend service life

- Qualified against the SAE J2360 standard.

Advanced gear oil technology, available in multiple options with varying viscosity index and grade.

- Operates in the coldest and warmest of temperatures, and can handle severe service conditions

- Defends against thermal and oxidative degradation, and extends gear and bearing life

Advanced gear oil technology, available in multiple options with varying viscosity index and grade.

- Resists heat degradation and deposits

- Preserves silicone seals and prevents leakage to resist acid, carbon and varnish formation

- Maintains viscosity for extended periods of time for excellent wear control and fuel efficiency

Advanced gear oil technology, available in multiple options with varying viscosity index and grade.

Conventional Gear Oil

| Product Name | Product Number | Product Data Sheet |

|---|---|---|

| THRIVE® Wide Range 80W-90 | Product Number140 | Product Data Sheet Download |

| THRIVE® Wide Range 85W-140 | Product Number139 | Product Data Sheet Download |

| Valvoline™ Heavy Duty Synthetic Gear Oil 80W-90 | Product Number | Product Data Sheet Link |

| Valvoline™ Heavy Duty Synthetic Gear Oil 85W-140 | Product Number | Product Data Sheet Link |

Synthetic Gear Oil

| Product Name | Product Number | Product Data Sheet |

|---|---|---|

| THRIVE® Synthetic 75W-140 | Product Number101 | Product Data Sheet Download |

| THRIVE® Synthetic 75W-90 | Product Number100 | Product Data Sheet Download |

| THRIVE® Synthetic 80W-90 | Product Number107 | Product Data Sheet Download |

| THRIVE® Synthetic 80W-140 | Product Number150 | Product Data Sheet Download |

| Valvoline™ Heavy Duty Synthetic 75W-90 | Product Number | Product Data Sheet Link |

| Castrol Syngear 75W-90 | Product Number | Product Data Sheet Link |

Synthetic Long Drain Gear Oil

| Product Name | Product Number | Product Data Sheet |

|---|---|---|

| THRIVE® Synthetic 75W-90 Long Drain | Product Number102 | Product Data Sheet Download |

| THRIVE® Synthetic 80W-140 Long Drain | Product Number125 | Product Data Sheet Download |

| Valvoline™ Syn Gard™ Gear Oil 75W-90 | Product Number | Product Data Sheet Link |

| Valvoline™ Syn Gard™ Gear Oil 80W-140 | Product Number | Product Data Sheet Link |