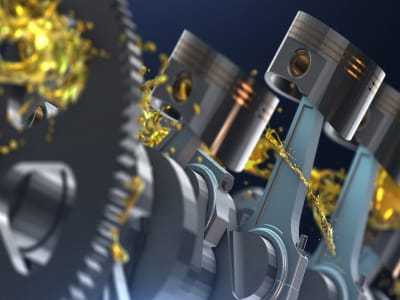

We’re more than just motor oil.

Lubricants only make up one piece of what our Intelligent Lubrication Solutions® are about. We also offer customized solutions to fit your business goals along with support services relating to lubrication reliability to ensure longer run times on your equipment to keep your business running smoothly. All products and services are expertly woven into customized solutions that help our customers assure the health of their manufacturing equipment, reduce unpredictable downtime, and extend the productive life of their machinery.